The Better Way to Manage Warm Air Ingress in Cold Chain Logistics.

When it comes to protecting cold stores from warm, humid air infiltration, many Cold Chain Logistics operators default to a familiar solution: installing dehumidification units within an air lock. It’s a method to temper the incoming air and manage condensation. But there’s a smarter, more energy-efficient alternative that can offer significant initial and long-term savings.

Understanding the challenge

Frozen cold stores must operate in tightly controlled conditions. Every time a door opens, especially in facilities with high traffic or rapid loading/unloading processes, there’s a risk of warm, moist air rushing in. This doesn’t just raise the internal temperature, it also causes frost build-up, compromises the food being stored, and forces refrigeration systems to work harder.

The default option

Air locks have traditionally helped by providing a buffer zone, often supported with dehumidification equipment to dry the incoming air. But this comes with drawbacks:

💸High installation and maintenance costs

💸Significant energy consumption

💸Additional equipment footprint and servicing requirements

The smarter alternative: prevent that warm air from entering your cold store in the first place!

At Thermoscreens we’ve developed an energy-efficient solution that directly addresses these issues, without the cost and complexity of a dehumidification system.

Our Cold Store Air Curtain is designed specifically for use at the entrance to frozen and chilled environments. It creates an invisible, high-velocity barrier of air that separates the internal and external atmospheres. This barrier slows and disrupts the natural airflow between zones, significantly reducing the ingress of warm, humid air into the cold store.

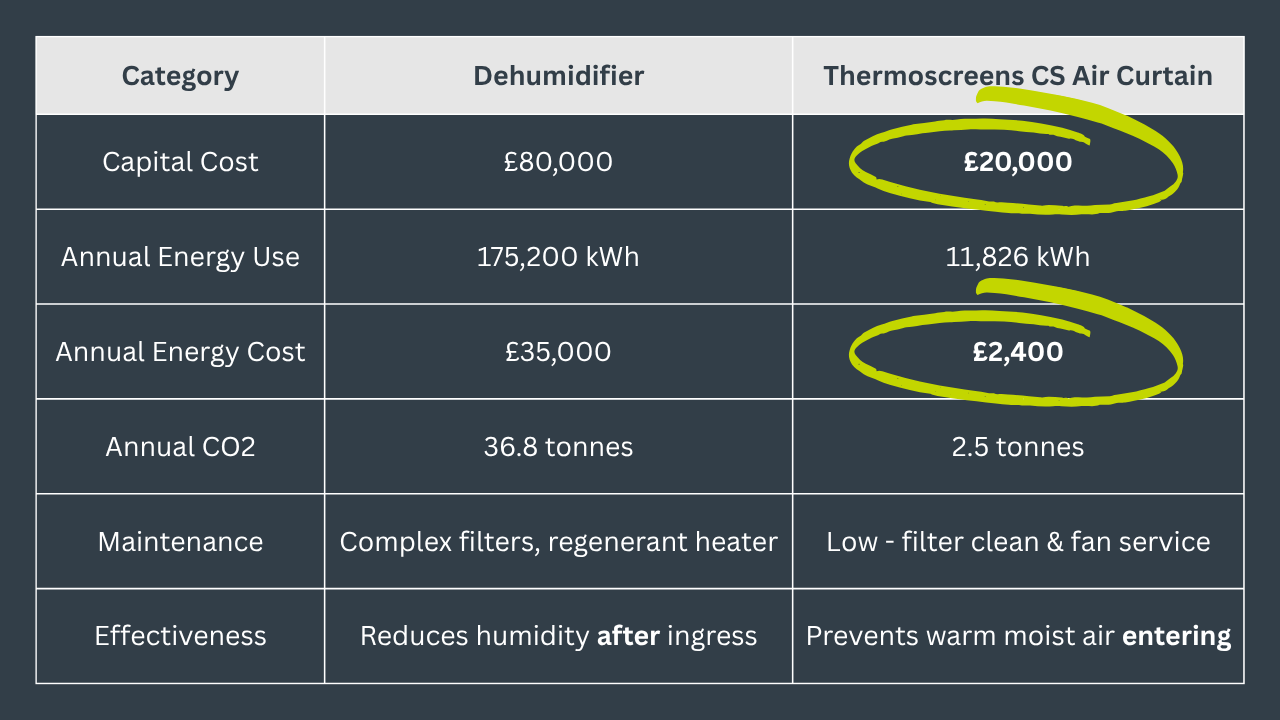

Let’s look at the difference:

Why it’s more cost-effective

Lower capital cost – Compared to installing a dehumidifier into an air lock, a Cold Store Air Curtain is simpler and faster to install, requiring fewer structural changes, less equipment and therefore lower upfront costs.

Reduced energy use – Air curtains use targeted airflow to manage warm air, not energy-intensive drying systems. This helps reduce the cold store’s overall energy consumption, especially in operations with frequent door openings.

Less refrigeration load – By minimising the entry of warm air, your refrigeration system doesn’t have to work as hard to maintain chilled and frozen temperatures. That means fewer cycles, less wear, and lower maintenance costs.

Improved safety – Our air curtain design reduces ice and frost build-up around doors and loading areas, as well as eliminating the need to UPVC strip curtains. The impact of this is fewer slip hazards, better visibility and uninterrupted operations.

If you’re considering dehumidification for your cold store air lock, talk to us first. You could save thousands in energy and maintenance costs over the life of your cold store!

Testimonials

“We’ve been very pleased with your products and would like to continue using them as a design feature in all our shops.”

- Project Manager, large ice-cream manufacturer.

“Wrapped up and gone before the lunch service, great turnaround from order to delivery.”

- Director, Restaurant in Aldwych

“Thank you for having an excellent working relationship with me, you are a credit to Thermoscreens.”

- Technical Engineer, HVAC

“The new air curtains in the freezer room have completely eliminated any ice and frost build up around the room, including the evaporators. As the main reason for cold room failure, this will undoubtedly help to reduce costly downtime, stock loss and maintenance calls.”

- Refrigeration Manager at leading supermarket

“The units we installed at Birmingham this week. We really enjoyed installing your units and would like to use them moving forward with the other stores.”

- Installer, Restaurant in Birmingham

“I would like to take this opportunity to thank you all for your performance, we have all been very impressed with your response to queries and turnaround of air curtains.”

- Installer, HVAC

“Thank you for all your support. We couldn’t have won this project without your assistance.”

- Senior engineer