Keeping Cold Chain Compliant On-board Cruise Ships.

In the cruise ship industry, food safety is non-negotiable. With hundreds or even thousands of passengers on board at any given time, ensuring that chilled and frozen goods are stored correctly is critical for both compliance and passenger wellbeing.

For those working in Food Safety, Quality, and Compliance roles, managing the cold chain on a moving vessel presents unique challenges. Chillers and freezers must maintain stable internal temperatures despite frequent door openings and high humidity environments.

We know the cold room challenges you’re up against

- Fluctuating internal temperatures

- Frost build-up on products and surfaces

- Overworked refrigeration equipment

- Non-compliance with food safety standards (such as HACCP or USPH)

- Increased maintenance demands and energy costs

Typically, uPVC strip curtains are used to attempt climate separation between the cold store and ambient air. Whilst strip curtains provide a physical barrier, they are prone to damage, allow air leakage through gaps, and can interrupt workflow by requiring physical contact during passage. Considering this, strip curtains need changing frequently which brings in environmental and sustainability concerns to consider.

But what if there was a way to strengthen your cold chain and forget the need for uPVC strip curtains…

The Solution: Thermoscreens Cold Chain Air Curtains

Thermoscreens’ Cold Chain Air Curtains are a compact, highly efficient solution specifically designed to prevent warm air and humidity from entering chilled or frozen storage areas, especially when travelling at sea.

Installed vertically or horizontally across cruise ship cold room doors, these systems create an invisible, high-velocity stream of air that forms a barrier between the warm external environment and the cooled internal space.

This delivers significant benefits for food safety and compliance teams:

Maintain cold room temperatures – Air curtains help stabilise internal conditions, preventing harmful fluctuations that could jeopardise product safety and lead to spoilage.

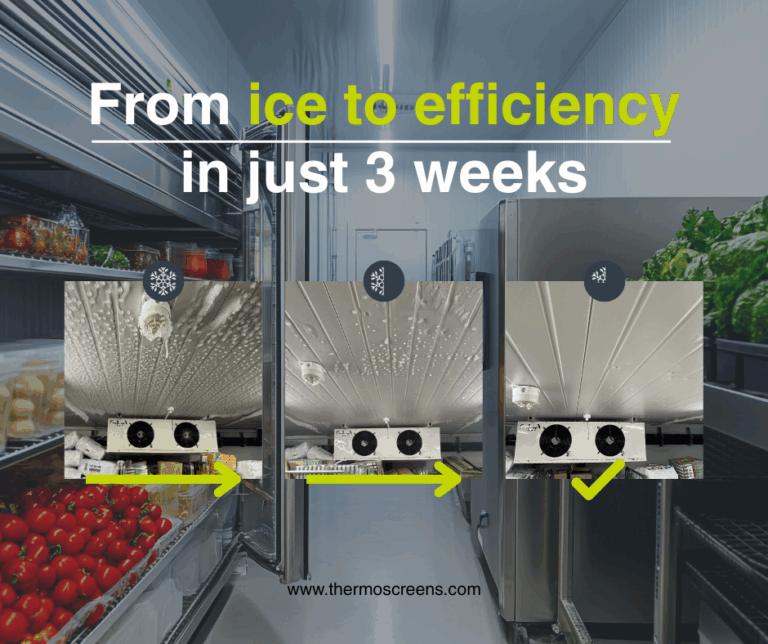

Reduce frost and condensation – By limiting moisture ingress, the systems reduce ice build-up throughout the entire freezer. This minimises defrost cycles, improves hygiene and decreases risks of slip and falls for staff.

Lower refrigeration load and energy costs – By keeping warm air out, refrigeration systems operate more efficiently, reducing energy consumption and prolonging equipment life. Also eliminating the need for expensive maintenance of uPVC strip curtains.

Support health & safety compliance – A more stable cold chain helps ensure HACCP, USPH, and other food safety protocols are maintained at every stage of the voyage.

Let us help you

Thermoscreens’ Cold Chain Air Curtains offer a practical, space-saving, and energy-efficient solution to enhance your onboard cold chain. We want to help your team uphold the highest standards of food safety and compliance, whilst considering sustainability.

Testimonials

“We’ve been very pleased with your products and would like to continue using them as a design feature in all our shops.”

- Project Manager, large ice-cream manufacturer.

“Wrapped up and gone before the lunch service, great turnaround from order to delivery.”

- Director, Restaurant in Aldwych

“Thank you for having an excellent working relationship with me, you are a credit to Thermoscreens.”

- Technical Engineer, HVAC

“The new air curtains in the freezer room have completely eliminated any ice and frost build up around the room, including the evaporators. As the main reason for cold room failure, this will undoubtedly help to reduce costly downtime, stock loss and maintenance calls.”

- Refrigeration Manager at leading supermarket

“The units we installed at Birmingham this week. We really enjoyed installing your units and would like to use them moving forward with the other stores.”

- Installer, Restaurant in Birmingham

“I would like to take this opportunity to thank you all for your performance, we have all been very impressed with your response to queries and turnaround of air curtains.”

- Installer, HVAC

“Thank you for all your support. We couldn’t have won this project without your assistance.”

- Senior engineer