Thermoscreens air curtains have multiple uses for multiple building sizes, ceiling heights, and doorway widths.

We understand that air curtains designed for industrial buildings such as cold stores, warehouses, food processing facilities and pharmaceutical sites have different needs and requirements. Read on to find out more about how our range of industrial air curtains can help your business or warehouse.

How do industrial air curtains work?

An industrial air curtain provides a sustainable solution for heating, ventilation and cooling of large areas and workspaces. Our air curtains work by providing an invisible barrier against the incoming air which reduces the amount of warm or cold air which escapes from the building.

As well as being an energy efficient solution to HVAC, they are designed primarily to enhance comfort ensuring that optimal working temperatures are maintained, and the goods are not disrupted by incorrect temperatures.

Why do I need an air curtain for my Cold Store

Cold stores are often used to store produce before being laid out on the shelves, it is imperative that cold stores are kept at a consistently low temperature to avoid the goods becoming waste. This is a challenge for many stores as the doorways are often in constant use due to the transportation of goods in and out of the room, these doors are also often left open by employees after use, resulting in the loss of cold air. A common issue that occurs with cold stores is the build-up of ice and fog around the doorway as a result of the low temperatures, this presents a health and safety risk for employees when transporting the goods. In order to combat these issues the Thermoscreens team have developed the CS Air Curtain.

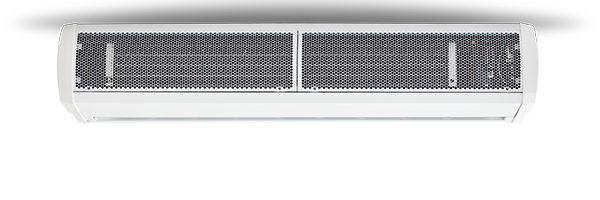

The CS has been engineered specifically for cold store applications. Developed with energy efficiency in mind, the CS uses advanced EC motor technology and has been designed to maintain optimum climate separation at temperatures as low as -25 degrees Celsius. The CS creates an invisible air barrier across the doorway, preventing the cold air from escaping outside. This means the chillers will use significantly less energy to keep the room at a low temperature. The enlarged openings in the inlet grill, along with the heating elements incorporated in the CS, result in built-in frost protection, which means that neither the unit nor the environment around it will ice up, resulting in a clear, safe passageway for goods to be transported in and out.

Pharmaceutical and refrigerated areas

The pharmaceutical industry heavily relies on ensuring that medicine, chemicals and other substances remain viable for their intended purpose. For many of these products, temperature plays a vital role in keeping their efficacy and suitability intact.

Implementing refrigerated areas into the pharmaceutical logistics strategy is an excellent method for retaining products’ viability whilst also extending the space and storage of the laboratory. With biological and chemical substances often needing stringent temperature regulations, using a refrigerated area can efficiently reach these temperatures and can be modified for storing the final product at the correct temperature needed, including medicine, vaccines and chemical agents.

The RA Air Curtain from Thermoscreens is the perfect solution for refrigerated areas. The RA Air curtain has been designed specifically for refrigerated areas where there are no sub-zero temperatures. Engineered with energy efficiency in mind, this innovative air curtain will prevent the exchange of air at the doorway meaning a consistent inside temperature can be achieved, protecting the valuable goods inside. The unit is fitted with an automatic door switch, meaning the air curtain will start up once the door is opened and will stop when closed, resulting in a reduction in energy costs.

Food Processing

Food processing facilities and abattoirs also must maintain a consistent temperature to keep their livestock safe and secure. While these temperatures will not be sub-zero like cold stores, they still need to be kept consistent to ensure they are inline with government legislation. This poses an issue for food processing companies, with energy costs on the rise and chillers still needing to run at the same capacity, it is imperative that costs are kept as low as possible. While an air curtain will help with this, choosing the right one is just as important. These facilities often include high-pressure chemical cleaning to keep the environment clean and hygienic, so it is important that the unit is IP rated, meaning it can withstand harsh chemical washdown.

The HE (Harsh Environments) air curtain is the perfect solution to combat these issues. Specifically designed for use in harsh environments with temperatures as low as 2 degrees Celsius, the HE air curtain delivers superior air velocity. Manufactured out of stainless steel, the unit has been granted an IP rating and is suitable for chemical cleaning and washdown. Having the unit installed above or alongside the doorway will help to save energy by reducing the workload of the chillers inside, this is due to preventing the exchange of warm or cold air from entering the room. This invisible air barrier will also prevent the ingress of flying insects due to the high velocity of air produced from the HE.

Warehouse

Warehouses and distribution centres are often large open spaces that have multiple entries and exits to allow the flow of goods in and out. These entries and exits allow for the outer air to enter the building which is normally at a much lower temperature than inside. This creates draughts that can disrupt the goods held in the warehouse especially if they need to be climate-controlled or force smaller elements such as swarf to fly around causing injury. On top of this, cold working conditions can dampen and lower the performance of your workers.

To help combat these issues, the Thermoscreens team has developed the IP2 air curtain. IP air curtains combine highly efficient climate separation with sturdy design and technical innovation to deliver outstanding energy savings with minimal maintenance. For maximum efficiency, IP units can be controlled via a contact switch. Whenever the door is opened the air curtain is activated and the thermal output increases. When the door is closed the air flow speed automatically decreases and thermal output stops. A time delay switch allows deactivation to set based on how frequently the door is used.

Speak to the team today.

Ready to purchase your industrial air curtains? Getting in touch with our team couldn’t be easier. Choose one of the options below, and a member of our expert team will be on hand to help:

- Call us today on 02476 384646,

- Send us an email to sales@thermoscreens.com

- Complete the online form, or click the links below.

Testimonials

“We’ve been very pleased with your products and would like to continue using them as a design feature in all our shops.”

- Project Manager, large ice-cream manufacturer.

“Wrapped up and gone before the lunch service, great turnaround from order to delivery.”

- Director, Restaurant in Aldwych

“Thank you for having an excellent working relationship with me, you are a credit to Thermoscreens.”

- Technical Engineer, HVAC

“The new air curtains in the freezer room have completely eliminated any ice and frost build up around the room, including the evaporators. As the main reason for cold room failure, this will undoubtedly help to reduce costly downtime, stock loss and maintenance calls.”

- Refrigeration Manager at leading supermarket

“The units we installed at Birmingham this week. We really enjoyed installing your units and would like to use them moving forward with the other stores.”

- Installer, Restaurant in Birmingham

“I would like to take this opportunity to thank you all for your performance, we have all been very impressed with your response to queries and turnaround of air curtains.”

- Installer, HVAC

“Thank you for all your support. We couldn’t have won this project without your assistance.”

- Senior engineer