Flying Fresh: Air Curtains Optimise Airline Catering Cold Storage.

The airline catering industry is a highly demanding sector when it comes to food quality, safety, and logistics. Behind every in-flight meal is a cold chain designed to preserve freshness, comply with strict hygiene regulations, and optimise operational efficiency.

However, these cold stores still face hidden challenges that quietly impact both product quality and energy costs.

Thermoscreens understand the challenges that you’re up against!

Door openings result in temperature fluctuations

In busy cold stores, doors are opened continuously to move trolleys, trays, and ingredients. Each opening allows warm, humid air to enter. This forces refrigeration units to work harder, risking temperature excursions that can impact product safety and hygiene.

Energy waste and high operating costs

Refrigeration is one of the largest energy consumers in airline catering and every unprotected door opening means more energy wasted to battle the incoming heat.

Ice build-up and safety risks

In frozen stores, air ingress leads to rapid ice build-up on floors, ceilings, and equipment. This increases maintenance costs and creates slip hazards for staff — adding safety concerns to the mix.

Strip curtain issues

PVC strip curtains create a physical barrier, making visibility difficult for staff walking through them. They also often require replacement after just 2 years in some cases.

So, how can the Air Curtain help?

Air curtains act as an invisible barrier, dramatically reducing the exchange of warm and cold air when doors are open.

Maintain stable temperatures

This invisible barrier helps cold rooms maintain stable target temperatures even during busy shifts. Therefore, supporting compliance with food safety standards and ensuring meals stay flying fresh.

Save energy and cut costs

By limiting temperature gains, air curtains reduce refrigeration system load. Therefore, significantly reducing energy losses.

In large-scale airline catering facilities running 24/7, the financial savings can be substantial – while also reducing your carbon footprint!

Minimise ice build-up

Air curtains greatly reduce the volume of humid air entering freezers, helping to prevent ice formation. This keeps floors safer, equipment running more efficiently, and maintenance needs lower.

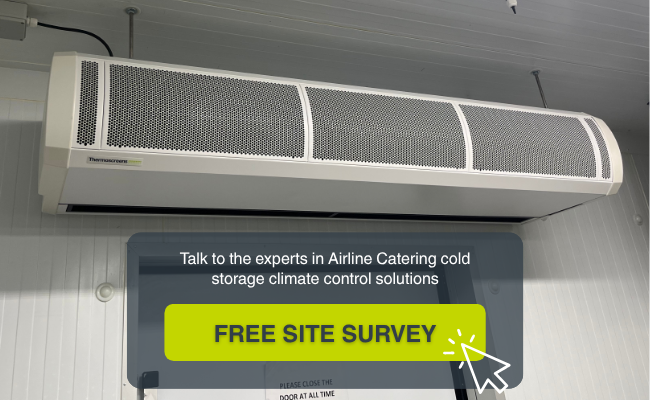

Give the team a call today to find out more

Testimonials

“We’ve been very pleased with your products and would like to continue using them as a design feature in all our shops.”

- Project Manager, large ice-cream manufacturer.

“Wrapped up and gone before the lunch service, great turnaround from order to delivery.”

- Director, Restaurant in Aldwych

“Thank you for having an excellent working relationship with me, you are a credit to Thermoscreens.”

- Technical Engineer, HVAC

“The new air curtains in the freezer room have completely eliminated any ice and frost build up around the room, including the evaporators. As the main reason for cold room failure, this will undoubtedly help to reduce costly downtime, stock loss and maintenance calls.”

- Refrigeration Manager at leading supermarket

“The units we installed at Birmingham this week. We really enjoyed installing your units and would like to use them moving forward with the other stores.”

- Installer, Restaurant in Birmingham

“I would like to take this opportunity to thank you all for your performance, we have all been very impressed with your response to queries and turnaround of air curtains.”

- Installer, HVAC

“Thank you for all your support. We couldn’t have won this project without your assistance.”

- Senior engineer